Overmoulding

We’re proud to provide our customers with an all-encompassing service they can rely upon, and our overmoulding service is no exception. At Dudley Associates Ltd, we take pride in being industry leaders in overmoulding, a specialised injection moulding technique that combines precision and innovation. As your trusted partner, we offer comprehensive overmoulding solutions designed to meet the unique requirements of your projects. Explore the world of overmoulding with Dudley Associates Ltd and discover why we are the ideal choice for your next injection moulding venture.

About Overmoulding

The process of overmoulding involves adding an additional layer of material to an existing component. Typically, this is either plastic on metal or plastic on plastic.

Plastic on metal

In this type of overmoulding, a metal part is inserted into the mould and a plastic polymer is injection-moulded around the metal part. This may entail some of the metal protruding externally beyond the plastic or the metal may be encased but with key parts exposed.

Why might this be needed?

There are many situations where this process is advantageous and it is very common in electrical and electronic areas (perhaps consider a two or three pin plug). Plastics are generally more lightweight and cheaper than metals, with very different conductive and thermal properties.

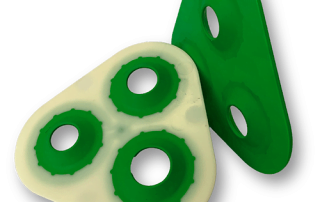

Plastic on plastic

We use this type of overmoulding with a range of different materials, often with a substrate made from ABS and an overmould with a TPE or acrylic. The skill here is to secure full bonding between the materials to ensure longevity and robustness. This is achieved through a combination of temperature, the speed and pressure of the injection process, and the cooling parameters.

Not all material combinations can be successfully bonded, but our team have built expertise over many years.

Why might this be needed?

The most common reasons we are asked to overmould plastic on plastic are:

o When a rigid, functional interior is required but an aesthetically pleasing exterior casing is desired;

o When a rigid, functional device is required but with a softer, tougher, easier to grip area on the outside;

o To establish a permanent seal which may well require a softer material than the rest of the component.

Mechanical overmoulding

Where a chemical bond is not possible, the overmould must be mechanically fixed to the substrate. This involves modifying the original part to have holes or cut-outs through which the overmoulded material can flow and set. The overmoulded material must fully encapsulate the substrate from both sides in the area of the fixing in order for the fixing to work. This complicates the moulding process as a shut-out is required on both sides of the substrate.

Get a Quote

“Datum Electronics has been dealing with Dudley Associates Ltd for many years. John is always very co-operative and willing to help. The quality of the product is always excellent and is delivered on-time, every time.”

“We were working with Dudley on a complex component that also involved another supplier, almost at the end of the development cycle the 2nd supplier let us down. John and the team at Dudley stepped in to rescue the project showing impressive technical ability and perseverance and leading us to a great end result.”

“I just wanted to share a quick note from myself and the team and let you know that we were delighted that you could meet both the costs and perhaps, more importantly, the timescale we had to work with. Very glad we decided to work with you again. It’s also worth mentioning that the support and advice that Dudley Associates provided to our design team while transitioning from their concept to the final tooling has been fantastic.”

“We have worked with Dudley Associates since 2009 on a variety of projects. Dudley Associates have always completed our work to a high standard and have been able to assist with the design and manufacture in an efficient, professional and timely manner. We look forward to our continued partnership with Dudley’s!

“Dudley Associates has been an important supplier for Palintest for many years, helping us to meet project requirements on time, on budget and within specification. The customer service from the team is excellent and they always go the extra mile to find the right solution. Thanks to everyone involved.”

“For the last 10 years Dudley Associates been considered a highly valued resource for the realisation of our moulded critical components, the expert advice in the final design & tooling we’ve always received and UK based precision engineering continues to provide us with the added assurance that our projects will complete successfully and on time.”

“We first approached Dudley to manufacture injection mould tools for us as we thought they offered excellent quality at a competitive price, and we were not disappointed. The tools are of excellent standard and delivered on time. Having had trouble free tools delivered, we now also take advantage of their in-house moulding facilities for small production run which again were completed on time without any problems.”

How it Works

Our intuitive overmoulding process takes care of everything on your behalf.

Discussion

Success in overmoulding starts with collaborative design. Our experienced engineers work closely with you to understand your product goals and design specifications. This collaborative approach ensures that the overmoulding process is seamlessly integrated into your product development, resulting in a final product that exceeds expectations.

No two overmoulding projects are the same. This is why we’ll thoroughly understand your requirements to ensure your product is tailor-made for your needs.

Manufacturing

The key to successful overmoulding lies in precision tooling. Dudley Associates Ltd’s advanced toolmaking capabilities enable us to create intricate moulds that facilitate the overmoulding process with unparalleled accuracy. Our commitment to precision ensures that every overmoulded component meets the highest standards of quality and consistency.

Equipped with state-of-the-art injection moulding machinery, Dudley Associates Ltd leverages advanced technology to execute the overmoulding process with efficiency and precision. Our injection moulding experts monitor each stage of production, ensuring that the overmoulded components are produced with consistent quality, whether it’s a small prototype run or a large-scale production.

Delivery

We’ll send out your fully-assembled parts using our approved courier partners. Alternatively, you can pick up your items if you wish.